Removing Buildup from Cement and Asphalt Storage Silos

Express Chipping, Inc. specializes in the comprehensive cleaning of silos in the ready-mix, cement, asphalt, and port industries. Buildup on silo walls can significantly hinder operations, causing bottlenecks and reducing storage capacity. Our removal services are designed to efficiently address these challenges, ensuring smooth material flow and optimal storage capacity.

Schedule Your

Service Today!

Ready-Mix Industry

Express Chipping, Inc. specializes in providing comprehensive ready-mix silo cleaning services designed to eliminate cement buildup and maintain optimal silo capacity. Our advanced techniques ensure smooth material flow, reducing production delays and operational inefficiencies. By addressing cement accumulation and enhancing material discharge rates, our professional cleaning services help ready-mix plants improve their productivity and minimize downtime.

Cement Accumulation

- Issue: Cement particles can adhere to the walls of silos over time, forming hardened layers or clumps due to moisture and compaction.

- Impact:

- Effective Capacity Reduction: Accumulated cement reduces the internal volume of the silo, limiting storage capacity.

- Impeded Material Flow: Hardened layers obstruct the free flow of cement during discharge, leading to blockages.

- Solution: Regular professional cleaning, including mechanical and chemical methods, to maintain full silo capacity and ensure smooth material discharge.

- Impact:

Production Delays

- Issue: Blockages and slow material flow from hardened cement can cause significant production hold-ups.

- Impact:

- Delayed Mixing: Interruptions in cement flow delay the mixing process.

- Delivery Schedules: Concrete delivery schedules are impacted, causing delays in project timelines.

- Solution: Efficient buildup removal using high-pressure water jetting and pneumatic tools to keep production lines running smoothly and without interruptions.

- Impact:

Increased Operational Costs

- Issue: Frequent maintenance and operational inefficiencies due to buildup.

- Impact:

- Maintenance Costs: Increased frequency of manual cleaning and repairs.

- Operational Inefficiencies: Higher energy consumption and labor costs.

- Solution: Scheduled maintenance programs, including periodic inspections and preventive cleaning, to minimize downtime and reduce long-term costs.

- Impact:

Our Solution: Comprehensive Ready Mix Silo Chipping Services

We offer a range of services designed to keep your ready mix trucks in optimal condition, ensuring seamless operations and preventing costly downtime. Here’s how we can help:

Chipping Techniques and Experience

Our chipping process involves learned techniques specifically evolved over 25 years in the ready-mix industry. We utilize powerful equipment and methodologies to ensure thorough chipping and maintenance of your ready mix silos.

Safety and Certification

Our technicians are OSHA certified, ensuring that all chipping operations are conducted safely and in compliance with industry regulations. Safety is our top priority, and we adhere to the highest standards to protect both our team and your equipment.

Off-Shift Operations

To minimize disruptions to your operations, we perform our chipping services in the evening during off hours. This ensures that your ready mix trucks are ready for use during regular working hours, maximizing productivity and efficiency.

Highest Ratings for Response Times

We pride ourselves on our quick response times and excellent customer service. Our service coordination team is always ready to address your chipping needs promptly, ensuring that any issues are resolved with minimal delay.

Impactful KPIs

- Silo Utilization Rate: Measures the percentage of available silo capacity being used.

- Flow Rate: The rate at which cement is discharged from the silo, measured in tons per hour.

- Downtime: Hours of production lost due to silo-related issues.

Types of Silos

- Vertical Silos: Common in ready-mix plants, these silos vary in capacity from 50 to 500 tons.

- Horizontal Silos: Used for storage and blending, often with capacities up to 1000 tons.

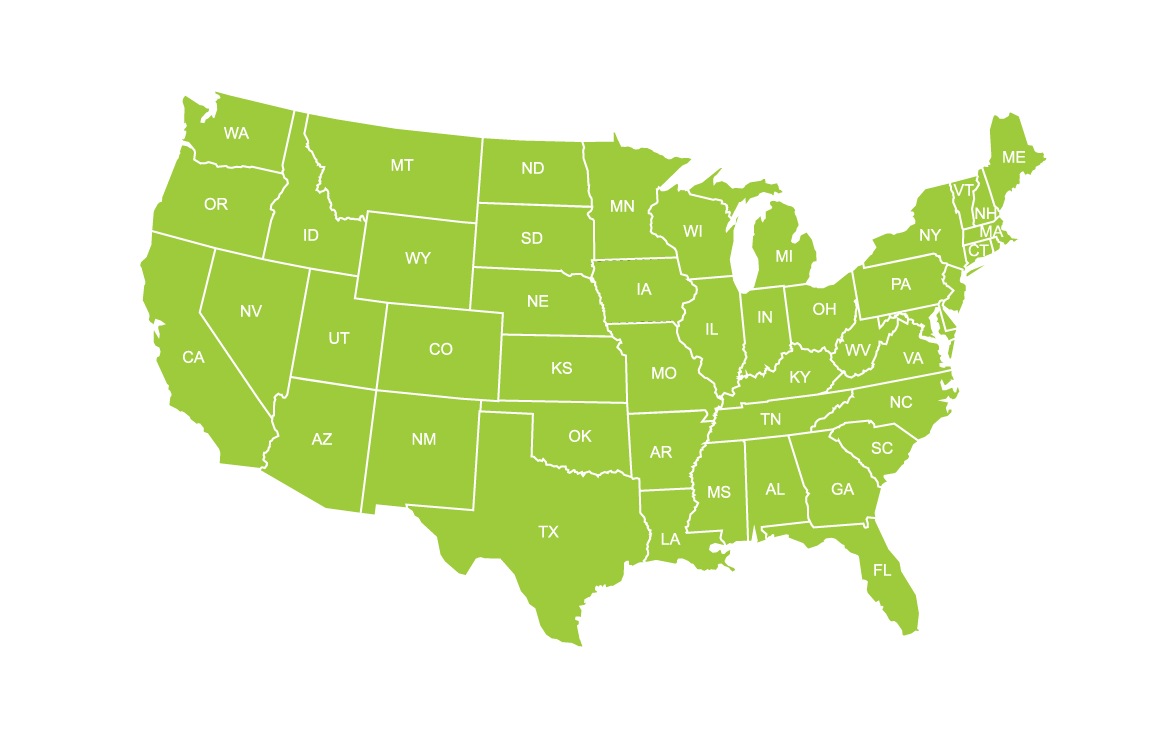

Locations to Serve You:

We Service Southern California

We Service Arizona

We Service Idaho

We Service North Florida

We Service New York

We Service Georgia

We Service South Carolina

We Service New Mexico

We Service Oregon

We Service Illinois

We Service Northern California

We Service Nevada

We Service South Florida

We Service Alabama

We Service New Jersey

We Service Texas

We Service North Carolina

We Service Colorado

We Service Washington

We Service Tennessee