Removing Buildup from Cement and Asphalt Storage Silos

Most Ready Mix plants have a couple of storage silos to hold finished cement in inventory for future needs. Buildup on the walls of the cement silos can have a negative financial impact on your company. The buildup can really slow down your material flow and decrease the capacity of the silo.

Dealing with these low flow or bottleneck issues and increasing your cement silo storage capacity may require our cement removal services. This is where Express Chipping, Inc. comes in.

Schedule Your

Service Today!

How It Works

First and Foremost, cleaning a cement silo from below should to ever be attempted. Poking from the bottom up inside the silo with any type of prodding equipment is asking for a catastrophe. The materials can become dislodged very easily and can suddenly bury you. Working from the top of the silo, Express Chipping ensures that all confined space regulations are followed as required by OSHA and probably by any local or regional safety departments. We have experience with all of the required fall protection equipment to ensure our employees safety and the safety of your employees is covered. We are specialists and want to ensure our customers that we are experienced with the nature and conditions of this type of job.

Prior to Express Chipping starting our process of cleaning your cement silo or vessel, we make sure that there is a path for loosened material to leave the silo. The discharge opening must be clean and there should be a takeaway mechanism at the bottom so the material does not build up so much that it blocks the opening. We make sure that the wall accumulation is undercut until it falls by its own weight. Express chipping makes sure that not too much is buildup to avoid damage to the silo.

If the buildup is bridged, plugged or we will use a method to open the hole. This method will eventually create a channel for the cement material to flow and our crew will finish using the traditional method.

Call us first ahead of time. If the cement silo is nearly closed you know that it is only going to get worse, call us and put it on schedule. That will allow us to properly plan the work and save money on mobilization and or overtime fees. This will also eliminate plant outage costs. Maintenance is much cheaper.

Express Chipping Silo Cement Removal Services offers many benefits to a cement ready mix plant. These include the recovery of material and storage capacity of your silo. Both of these are operating expenses that you already paid for. Sometimes the value of the recovered materials is enough to pay for the cleaning costs. These are expenses that are already in the books so staying on top of your silo maintenance is important. Similar to concrete chipping your trucks, the economic benefit of maximizing your distribution strategy as well as your material storage capacity can turn into an investment rather than an expense.

Express Chipping focuses on plant efficiencies and keeping your silo clean and avoiding a clogged or slow silo will avoid plant operation interference and positively impact your plants finances. Call us today to experience our Silo Maintenance Programs.

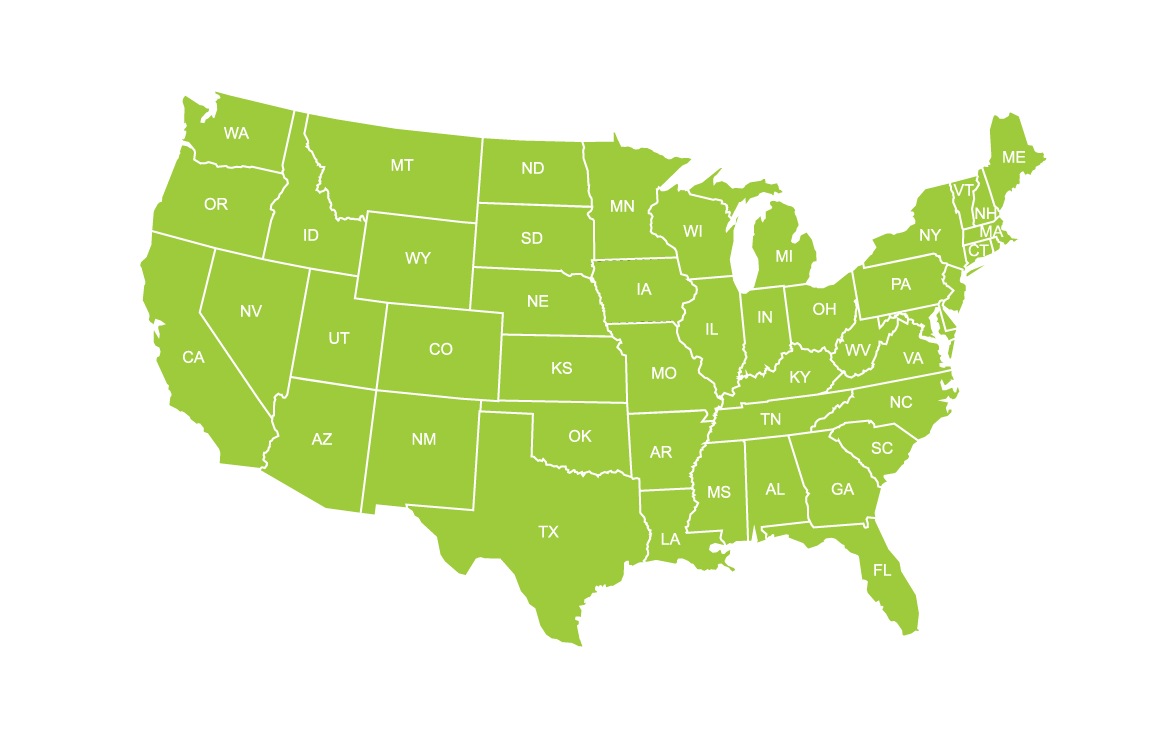

Locations to Serve You:

We Service Southern California

We Service Arizona

We Service Idaho

We Service North Florida

We Service New York

We Service Georgia

We Service South Carolina

We Service New Mexico

We Service Oregon

We Service Illinois

We Service Northern California

We Service Nevada

We Service South Florida

We Service Alabama

We Service New Jersey

We Service Texas

We Service North Carolina

We Service Colorado

We Service Washington

We Service Tennessee