Cement Industry

Express Chipping, Inc. offers specialized cement silo cleaning services tailored to the unique challenges of the cement industry. Our thorough cleaning methods effectively remove hardened cement buildup, maximizing storage efficiency and improving operational performance. By maintaining silo capacity and ensuring contaminant-free storage, our services help cement plants streamline logistics, reduce maintenance costs, and uphold the highest product quality standards.

Schedule Your

Service Today!

Cement Industry Overview

Storage Efficiency

- Issue: Buildup of cement on silo walls reduces storage efficiency.

- Impact:

- Capacity Constraints: Limits the amount of cement that can be stored.

- Logistical Issues: Requires more frequent deliveries, increasing transportation costs.

- Solution: Comprehensive cleaning using rotary cleaning heads and vacuum systems to maximize storage capacity and streamline logistics.

- Impact:

Operational Inefficiency

- Issue: Buildup affects the smooth flow of materials from silos.

- Impact:

- Production Delays: Slows down the overall production process.

- Energy Consumption: Increases the energy required to maintain flow rates.

- Solution: Effective cleaning solutions, including acoustic cleaners and industrial vibrators, to enhance flow rates and operational efficiency.

- Impact:

Quality Control

- Issue: Contamination from old cement residues can affect new batches.

- Impact:

- Product Quality: Compromises the quality and consistency of cement.

- Customer Satisfaction: Leads to potential complaints and returns.

- Solution: Thorough cleaning to ensure high-quality standards are met, using high-efficiency dust collection systems and automated cleaning technologies.

- Impact:

Our Solution: Comprehensive Cement Silo Chipping Services

We offer a range of services designed to keep your ready mix trucks in optimal condition, ensuring seamless operations and preventing costly downtime. Here’s how we can help:

Chipping Techniques and Experience

Our chipping process involves learned techniques specifically evolved over 25 years in the ready-mix industry. We utilize powerful equipment and methodologies to ensure thorough chipping and maintenance of your cement silos.

Safety and Certification

Our technicians are OSHA certified, ensuring that all chipping operations are conducted safely and in compliance with industry regulations. Safety is our top priority, and we adhere to the highest standards to protect both our team and your equipment.

Off-Shift Operations

To minimize disruptions to your operations, we perform our chipping services in the evening during off hours. This ensures that your ready mix trucks are ready for use during regular working hours, maximizing productivity and efficiency.

Highest Ratings for Response Times

We pride ourselves on our quick response times and excellent customer service. Our service coordination team is always ready to address your chipping needs promptly, ensuring that any issues are resolved with minimal delay.

Specific KPIs

- Storage Utilization Rate: Measures how efficiently the storage capacity is used.

- Material Flow Efficiency: The rate at which materials are transferred from storage to production.

- Product Quality Index: Monitors the quality and consistency of the cement produced.

Types of Silos

- Welded Silos: Permanent structures with capacities up to 10,000 tons.

- Bolted Silos: Modular and transportable, typically ranging from 500 to 5,000 tons.

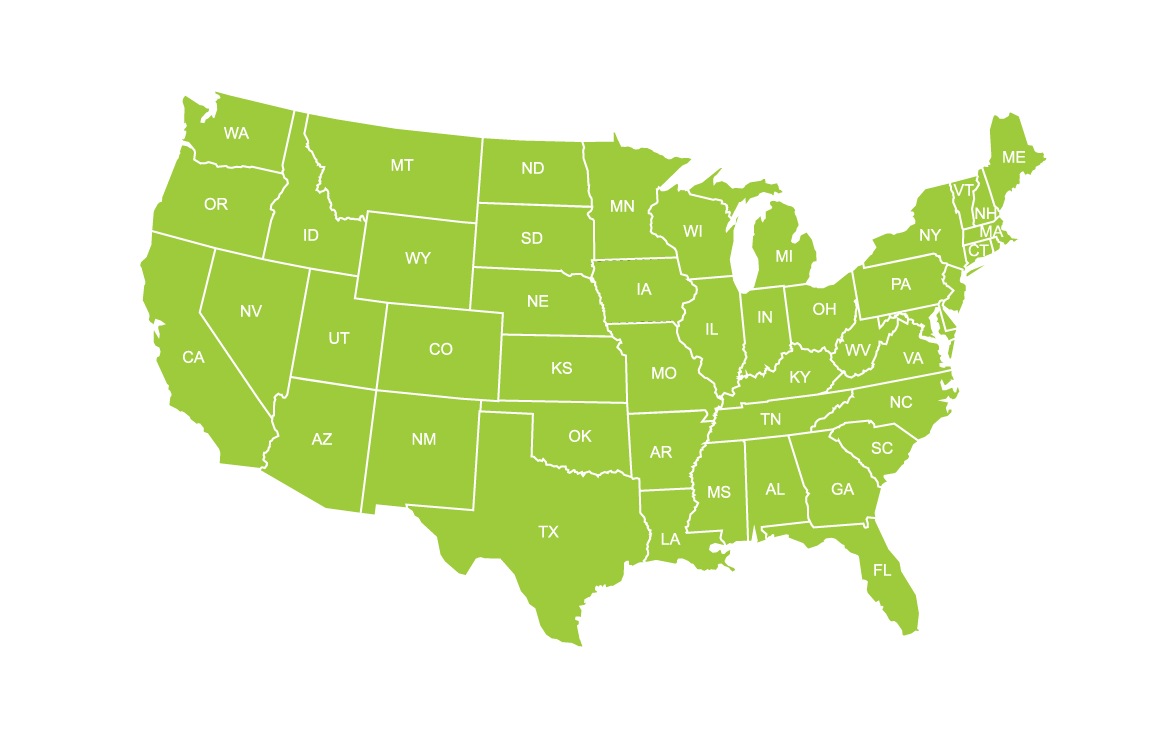

Locations to Serve You:

We Proudly Service Southern California – Click to Learn More!

We Proudly Service Arizona – Click to Learn More!

We Proudly Service Idaho – Click to Learn More!

We Proudly Service North Florida – Click to Learn More!

We Proudly Service New York – Click to Learn More!

We Proudly Service Georgia – Click to Learn More!

We Proudly Service South Carolina – Click to Learn More!

We Proudly Service New Mexico – Click to Learn More!

We Proudly Service Oregon – Click to Learn More!

We Proudly Service Illinois – Click to Learn More!

We Proudly Service Northern California – Click to Learn More!

We Proudly Service Nevada – Click to Learn More!

We Proudly Service South Florida – Click to Learn More!

We Proudly Service Alabama – Click to Learn More!

We Proudly Service New Jersey – Click to Learn More!

We Proudly Service Texas – Click to Learn More!

We Proudly Service North Carolina – Click to Learn More!

We Proudly Service Colorado – Click to Learn More!

We Proudly Service Washington – Click to Learn More!

We Proudly Service Tennessee – Click to Learn More!

We Proudly Service Utah – Click to Learn More!

We Proudly Service Wyoming – Click to Learn More!

We Proudly Service Ohio – Click to Learn More!

We Proudly Service Pennsylvania – Click to Learn More!

We Proudly Service Arkansas – Click to Learn More!

We Proudly Service Kentucky – Click to Learn More!

We Proudly Service Virginia – Click to Learn More!

We Proudly Service West Virginia – Click to Learn More!