Keep Your Plant Mixers Running Smoothly:

Maintaining the efficiency of your plant mixers is critical to all ready-mix companies. Issues like machinery stoppages, blockages, buildup from special mixes can severely impact your operations. When a concrete load stalls or stops during unloading, the risk of the load hardening increases, leading to difficult removal processes and potential machinery damage.

Schedule Your

Service Today!

Why Plant Mixer Chipping is Essential

Stalling or stoppage during the unloading process is a common issue that can have detrimental effects:

- Enhanced Mixer Performance: Regular chipping of your plant mixer prevent concrete buildup, ensuring that the mixer blades and drum operate at peak efficiency. This leads to a more consistent mix quality, essential for producing high-grade concrete that meets industry standards.

- Extended Equipment Lifespan: Concrete buildup can cause undue wear and tear on your plant mixer’s components, leading to premature failure. By keeping your mixers clean, you significantly extend the lifespan of your equipment, maximizing your return on investment and reducing capital expenditures on new machinery.

- Improved Safety for Workers: Concrete buildup can create hazardous working conditions, such as blockages or unexpected equipment malfunctions. Regular chipping and maintenance reduce these risks, contributing to a safer work environment and helping you comply with stringent OSHA safety regulations.

- Energy Efficiency: A plant mixer free from concrete buildup requires less power to operate. The mixer can run more smoothly, consuming less energy and reducing your operational costs. Over time, this can result in substantial savings on energy bills and a lower environmental impact.

- Consistent Batch Quality: Concrete buildup can lead to inconsistent mixing and batching, affecting the quality and uniformity of your concrete. Regular cleaning ensures that each batch meets the required specifications, maintaining the integrity of your products and enhancing customer satisfaction.

Our Solution: Comprehensive Plant Mixer Chipping Services

We offer a range of services designed to keep your plant mixers in optimal condition, ensuring seamless operations and preventing costly downtime. Here’s how we can help:

Chipping Techniques and Experience

Our chipping process involves learned techniques specifically evolved over 25 years in the ready-mix industry. We utilize powerful equipment and methodologies to ensure thorough chipping and maintenance of your plant mixers.

Safety and Certification

Our technicians are OSHA certified, ensuring that all chipping operations are conducted safely and in compliance with industry regulations. Safety is our top priority, and we adhere to the highest standards to protect both our team and your equipment.

Off-Shift Operations

To minimize disruptions to your operations, we perform our chipping services in the evening during off hours. This ensures that your plant mixers are ready for use during regular working hours, maximizing productivity and efficiency.

Highest Ratings for Response Times

We pride ourselves on our quick response times and excellent customer service. Our service coordination team is always ready to address your chipping needs promptly, ensuring that any issues are resolved with minimal delay.

Customized Maintenance Plans

- Portable Chipping Units: Our portable chipping crews are easily mobilized to remote locations, ensuring consistent service.

- Logistical Support: We offer logistical support to help manage the challenges of operating in remote or temporary sites.

- Tailored Solutions: Our maintenance plans are specifically designed to meet the unique needs of your ready mix plant, ensuring that all equipment and processes receive the attention they require for optimal performance.

- Flexible Scheduling: We offer flexible maintenance schedules that can be adjusted to fit your plant’s operational hours, minimizing disruptions and ensuring that maintenance activities do not interfere with production.

- Comprehensive Coverage: Our customized plans cover all aspects of your plant’s operations, from plant mixers to auxiliary equipment, providing a thorough and holistic approach to concrete chipping.

- Expert Support: Benefit from the expertise of our certified technicians who understand the intricacies of ready mix operations and are dedicated to keeping your plant running smoothly and efficiently.

- Cost-Effective: Our customized maintenance plans are designed to maximize your investment by preventing costly breakdowns and extending the lifespan of your equipment, ultimately saving you money in the long run.

Ensuring the efficiency of your plant mixers is crucial for maintaining seamless operations in the ready mix industry. Our comprehensive chipping services, performed by OSHA certified technicians, are designed to tackle the common challenges of machinery failure, water unavailability, and the unique demands of temporary mobile plants. We work during off-shift hours to minimize disruptions and pride ourselves on our fast response times.

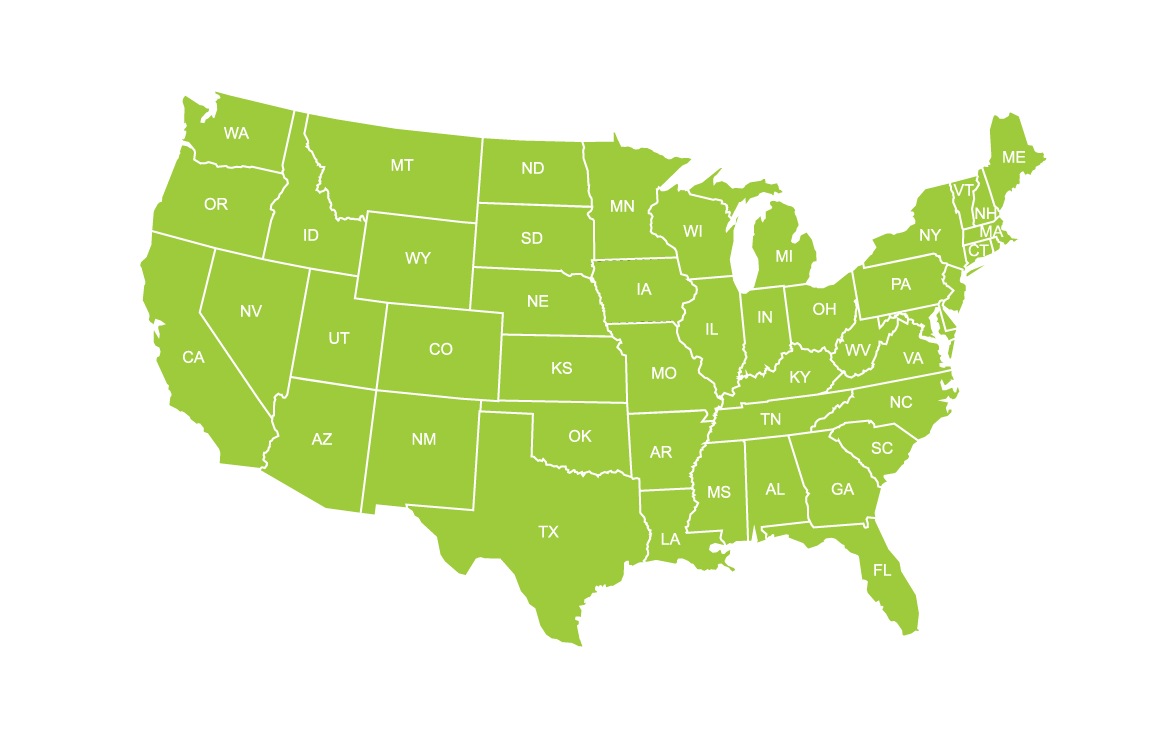

Locations to Serve You:

We Proudly Service Southern California – Click to Learn More!

We Proudly Service Arizona – Click to Learn More!

We Proudly Service Idaho – Click to Learn More!

We Proudly Service North Florida – Click to Learn More!

We Proudly Service New York – Click to Learn More!

We Proudly Service Georgia – Click to Learn More!

We Proudly Service South Carolina – Click to Learn More!

We Proudly Service New Mexico – Click to Learn More!

We Proudly Service Oregon – Click to Learn More!

We Proudly Service Illinois – Click to Learn More!

We Proudly Service Northern California – Click to Learn More!

We Proudly Service Nevada – Click to Learn More!

We Proudly Service South Florida – Click to Learn More!

We Proudly Service Alabama – Click to Learn More!

We Proudly Service New Jersey – Click to Learn More!

We Proudly Service Texas – Click to Learn More!

We Proudly Service North Carolina – Click to Learn More!

We Proudly Service Colorado – Click to Learn More!

We Proudly Service Washington – Click to Learn More!

We Proudly Service Tennessee – Click to Learn More!

We Proudly Service Utah – Click to Learn More!

We Proudly Service Wyoming – Click to Learn More!

We Proudly Service Ohio – Click to Learn More!

We Proudly Service Pennsylvania – Click to Learn More!

We Proudly Service Arkansas – Click to Learn More!

We Proudly Service Kentucky – Click to Learn More!

We Proudly Service Virginia – Click to Learn More!

We Proudly Service West Virginia – Click to Learn More!

Lose Your Load?

We Have the Most Effective Solution for the Readymix Industry!

A common issue that can be detrimental to concrete pouring is stalling or stoppage during the unloading process. Stoppage due to machinery failure can lead to the entire concrete load hardening, which will create a difficult removal process and the possibility of damage to the machinery.

That is where LoadKill can help. LoadKill is a ready mix concrete hydration inhibitor that works to decrease the psi levels in the concrete. Now what does that mean? Psi is what measures the strength of concrete, with a higher psi level meaning the concrete is stronger and tougher to handle. LoadKill works to decrease psi levels which weakens the concrete, making it less difficult to remove concrete from ready mix concrete trucks and plant mixers.

Schedule Your

Service Today!

How It Works

Concrete hydration is the process that causes the actual concrete itself to harden and take on its solid form that we see everyday. LoadKill inhibits the concrete hydration process to slow the hardening of concrete in order to allow easier removal. LoadKill will delay the hydration process long enough to allow the killed load to be removed from the drum without hardening on the interior.

Just pour the entirety of the 3.5 gallon jug into the drum immediately after mechanical stalling our stoppage of unloading. If it is possible, rotate the drum until the load has been killed. This will decrease the wash out time and allow for a quick removal process of the killed load.

LoadKill comes in an easy to use and refillable 3.5-gallon container. The product has been field tested by professionals in the concrete industry and has consistently proven to be effective. LoadKill is an all-natural product and safe to use, and its compact container can easily be stored in concrete trucks. Most importantly, in the event of stalling it will save you both time and money in the concrete removal process.

Don’t let something as simple as a breakdown cost you thousands of dollars in concrete removal and repairs.

Locations to Serve You:

We Service Southern California

We Service Arizona

We Service Idaho

We Service North Florida

We Service New York

We Service Georgia

We Service South Carolina

We Service New Mexico

We Service Oregon

We Service Illinois

We Service Northern California

We Service Nevada

We Service South Florida

We Service Alabama

We Service New Jersey

We Service Texas

We Service North Carolina

We Service Colorado

We Service Washington

We Service Tennessee

Lose Your Load?

We Have the Most Effective Solution for the Readymix Industry!

A common issue that can be detrimental to concrete pouring is stalling or stoppage during the unloading process. Stoppage due to machinery failure can lead to the entire concrete load hardening, which will create a difficult removal process and the possibility of damage to the machinery.

That is where LoadKill can help. LoadKill is a ready mix concrete hydration inhibitor that works to decrease the psi levels in the concrete. Now what does that mean? Psi is what measures the strength of concrete, with a higher psi level meaning the concrete is stronger and tougher to handle. LoadKill works to decrease psi levels which weakens the concrete, making it less difficult to remove concrete from ready mix concrete trucks and plant mixers.

Schedule Your

Service Today!

How It Works

Concrete hydration is the process that causes the actual concrete itself to harden and take on its solid form that we see everyday. LoadKill inhibits the concrete hydration process to slow the hardening of concrete in order to allow easier removal. LoadKill will delay the hydration process long enough to allow the killed load to be removed from the drum without hardening on the interior.

Just pour the entirety of the 3.5 gallon jug into the drum immediately after mechanical stalling our stoppage of unloading. If it is possible, rotate the drum until the load has been killed. This will decrease the wash out time and allow for a quick removal process of the killed load.

LoadKill comes in an easy to use and refillable 3.5-gallon container. The product has been field tested by professionals in the concrete industry and has consistently proven to be effective. LoadKill is an all-natural product and safe to use, and its compact container can easily be stored in concrete trucks. Most importantly, in the event of stalling it will save you both time and money in the concrete removal process.

Don’t let something as simple as a breakdown cost you thousands of dollars in concrete removal and repairs.